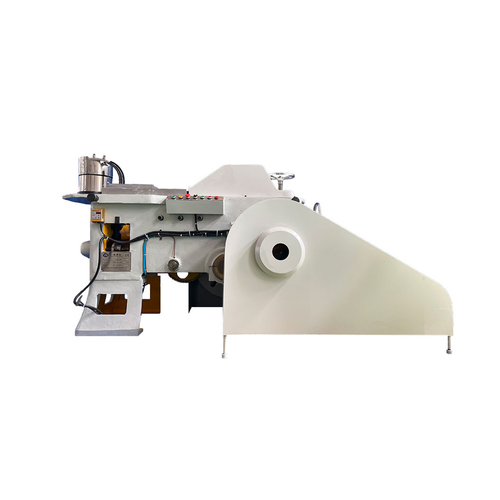

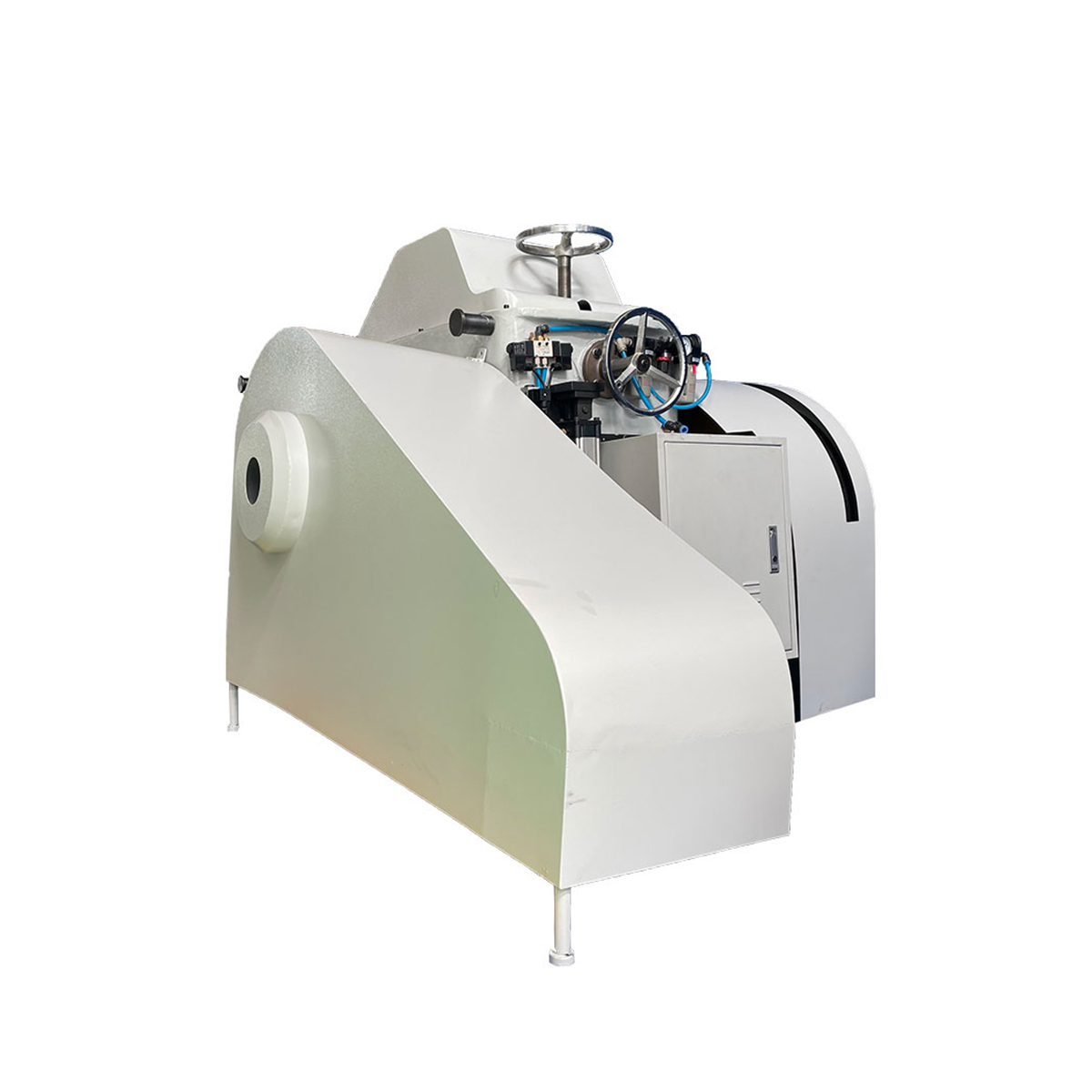

Punching Machine for glue tubes making machine

Product Details:

- Product Type Other

- Technology Other

- Power Source Electricity

- Operating Type Automatic

- Power 4370 Watt (w)

- Pressure 0.6~0.8 mpa

- Surface Treatment Painted

- Click to View more

Punching Machine for glue tubes making machine Price And Quantity

- 38000 USD ($)/Set

- 1 Set

Punching Machine for glue tubes making machine Product Specifications

- 3000 Kilograms (kg)

- Automatic

- 4370 Watt (w)

- 1 year

- 2200*1460*1450 Millimeter (mm)

- Other

- New

- Painted

- White

- 60 Pcs/min

- Electricity

- 0.6~0.8 mpa

- Other

Punching Machine for glue tubes making machine Trade Information

- Shanghai

- Letter of Credit at Sight (Sight L/C) Telegraphic Transfer (T/T)

- 50 Set Per Year

- 3 Months

- Yes

- Contact us for information regarding our sample policy

- STANDARD EXPORT PACKING

- Asia North America Middle East

- All India

- CE

Product Description

LJD series high-speed horizontal cold extrusion machine, also known as high-speed horizontal punch, is a new generation of high-speed aluminum tube / can extrusion equipment developed and designed by our company. It is a special production equipment for extruding aluminum slug into embryo tube or other shape cylinder. Principle: the slug bowl automatically arranges and regularly sends the aluminum slugs into the blanking guide rail, and accurately sends the aluminum slugs into the press mould by the feeding gripper. Under the action of the crank link swing rod and the slider, the gap between the tip of punch and the mould hole controls the thickness of the tube. Through the annular gap between the carbide ring and the tip of punch, the round sheet is cold extruded once to form a blank tube and automatically stripper The chain outputs the billet in an orderly manner. The equipment can also set different extrusion process according to customer requirements.

RFQ

1. Who are we?

We are based in Jiangsu, China, start from 2020,sell to Southeast Asia(35.00%),Mid East(20.00%),South Asia(20.00%),Domestic Market(10.00%),Africa(5.00%),Central America(5.00%),North America(4.00%),Eastern Europe(1.00%). There are total about 51-100 people in our office.

2. How can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3. What can you buy from us?

Automatic Aluminum Tube Line,Trimming Machine,Horizontal Extrusion Machine,Printing Machine,Capping machine

4. Why should you buy from us not from other suppliers?

1. Core staff have worked in this industry for more than 15 years on average.

2. More than 10 R & D personnel.

3. More than 10 senior engineers.

4. Door-to-door service team.

5. 7*24 online after-sales team.

6. Sufficient spare parts, fast delivery.

5. What services can we provide?

Accepted Delivery Terms: FOB, CFR, CIF, EXWï¼›

Accepted Payment Currency: USD, EUR, CNY;

Accepted Payment Type: T/T,L/C;

Language Spoken:English,Chinese

Other Products in 'Aluminum Tube Line' category

|

WUXI XINRUN PACKAGING MACHINERY TECHNOLOGY

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese