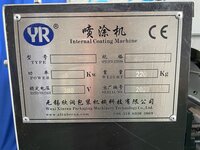

Internal Lacquering Machine for aluminum soft tubes making machines

Product Details:

- Product Type Other

- Technology Other

- Power Source Electricity

- Operating Type Automatic

- Power 5600 Watt (w)

- Pressure 5.5 Bar

- Surface Treatment Painted

- Click to View more

Internal Lacquering Machine for aluminum soft tubes making machines Price And Quantity

- 34000 USD ($)/Set

- 1 Set

Internal Lacquering Machine for aluminum soft tubes making machines Product Specifications

- 2200 Kilograms (kg)

- 3000*1600*2150 Millimeter (mm)

- Automatic

- 60 Pcs/min

- New

- Other

- 5600 Watt (w)

- Other

- White

- 5.5 Bar

- Electricity

- Painted

- Yes

Internal Lacquering Machine for aluminum soft tubes making machines Trade Information

- Shanghai

- 50 Set Per Year

- 30 Days

- Yes

- Contact us for information regarding our sample policy

- Standard Export Packaging

- All India

- CE

Product Description

PTD01 is internal lacquering machine which sprays epoxy resin on the inner surface of tubes to protect aluminum from forming any chemical reaction with the contents filled inside.

Germ tubes from annealing oven drop into the tube slot and then are pushed into sprayer cup plates by push rod. The first spray gun stretches into tubes and blows out compressed air, eliminating dust and impurities. Germ tubes then rotate with turntable and move to the next station. The second spray gun sprays fluid while cup plate rotates at high speed under the drive of flat belt to make the fluid cover the internal wall uniformly. cup plate moves to next station and repeats the former action to finish the second spraying. Usually, the first spray focuses on side walland the second straight injection.

Other Products in 'Aluminum Tube Line' category

|

WUXI XINRUN PACKAGING MACHINERY TECHNOLOGY

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese