Trimming Cum Brushing Machine for hair dye tubes making machine

Product Details:

- Product Type Other

- Technology Other

- Power Source Electricity

- Operating Type Automatic

- Power 2200 Watt (w)

- Pressure 0.6 mpa

- Surface Treatment Painted

- Click to View more

Trimming Cum Brushing Machine for hair dye tubes making machine Price And Quantity

- 18000 USD ($)/Set

- 1 Set

Trimming Cum Brushing Machine for hair dye tubes making machine Product Specifications

- 1300 Kilograms (kg)

- White

- 60 Pcs/min

- Other

- Automatic

- Yes

- 210017501100 Millimeter (mm)

- 2200 Watt (w)

- New

- Electricity

- 0.6 mpa

- Other

- Painted

Trimming Cum Brushing Machine for hair dye tubes making machine Trade Information

- Shanghai

- 50 Set Per Year

- 30 Days

- Yes

- Contact us for information regarding our sample policy

- Standard Export Packaging

- Asia North America Middle East

- All India

- CE

Product Description

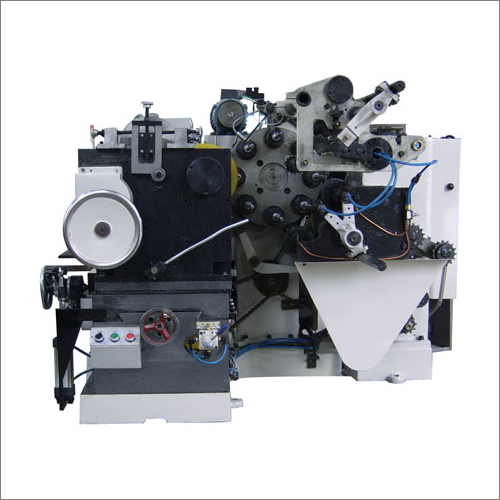

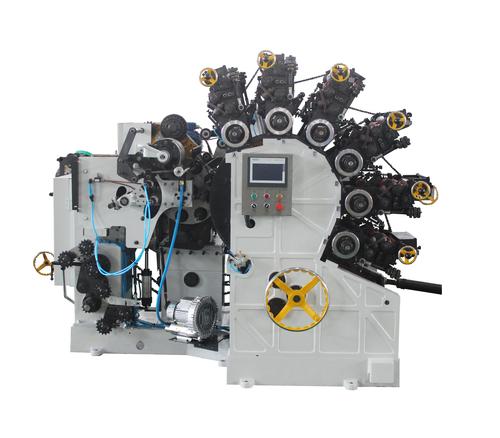

LWD01 is the aluminum tube thread and length trimming machine. It is the specialized equipment of the aluminum tube production line. It is the necessary part of metal collapsible tube line for consumer goods and medicine products. It can work alone or form a production line by connecting with other machines.

The main working procedures include trimming the tube nozzle, processing nozzle thread, polishing tube shoulder and length trimming to required length.

Germ tubes from charging conduit are pushed and inserted over mandrel, the expand mandrel expand to fasten the tubes on the mandrel, and revolves at high speed with the tubes. During the procedure, the tube end is trimmed by the knife to the required length. The tube nozzle is trimmed and form thread formed with chaser rolls,as per specifications. Next, the brush driven by motor polishes the head and shoulder of the tubes and the body of tubes is made smooth and straight, which is helpful for unloading tubes.

The last working station is for unloading materials. The unloading board controlled by cam pushes the processed tubes out from the mandrel. Following the flat belt, the tubes come to the charging conduit which can connect with conveyor chain of annealing oven.

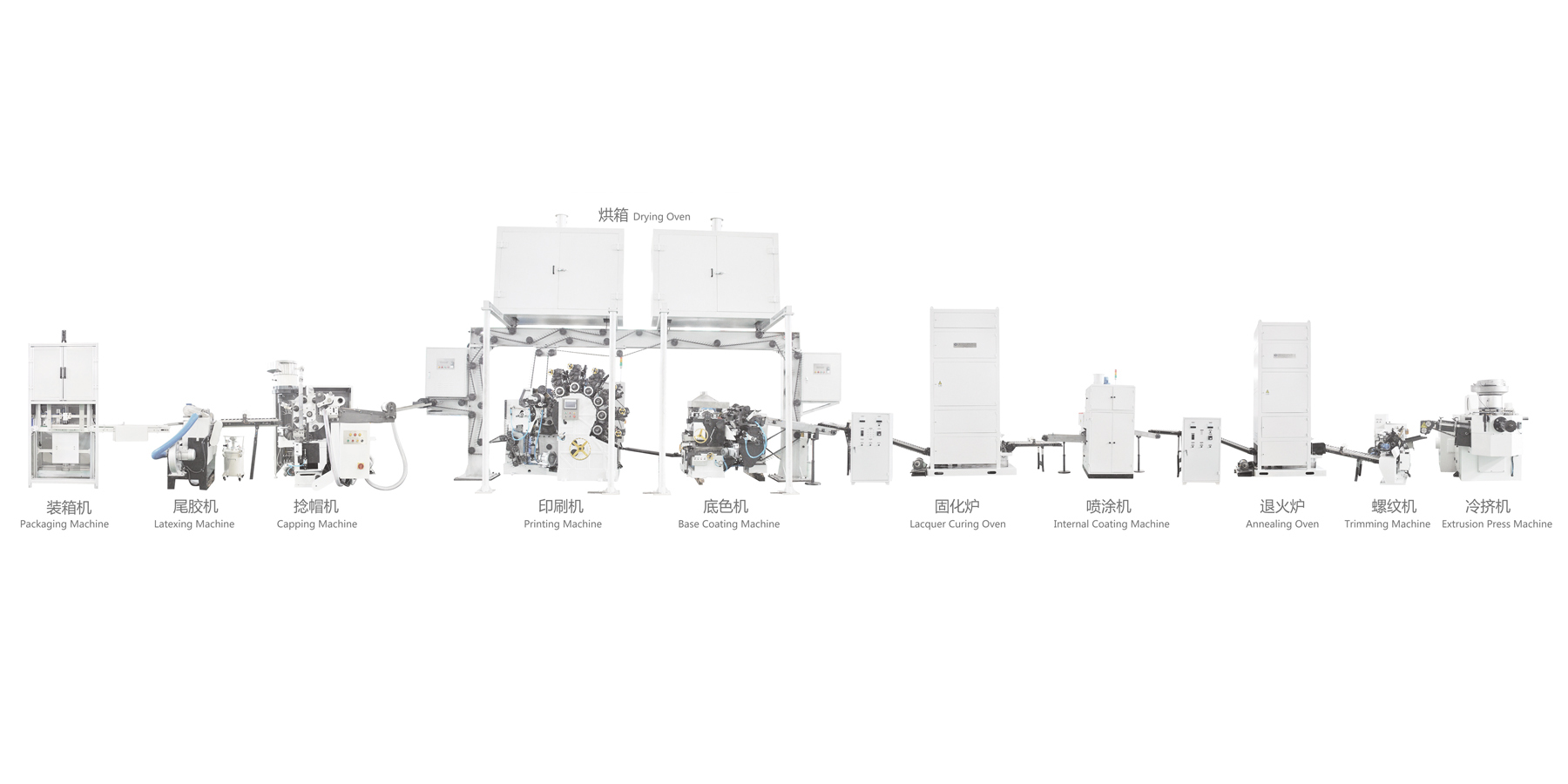

Aluminum soft tubes line is also called aluminum collapsible tubes line. It is mainly used to produce various aluminum collapsible tubes, small aluminum barrel or cans. The line is applied to filling products like ointment, artistic pigment, cosmetics, sealant, toothpaste, shoe polish, AB glue, hair dye, tomato sauce, chocolate sauce, instant adhesive, pen or marker barrel, cigar, etc.

The aluminum tubes lines produced by our company are fully automatic. Each equipment of the series can work alone or form full or partial. The main machines include LJD01/02 Extrusion press, LWD01 Trimmer, THD01 Annealing oven, PTD01 Internal lacquering machine, GHD01 Lacquer curing oven, DYD01 Base-coating machine, YSD01 4-color, YSD02 5-color and YSD03 6-color printing machine, HXD01 Drying oven, NMD01 Capping machine and WTD01 Latexing machine.

Other Products in 'Aluminum Tube Line' category

|

WUXI XINRUN PACKAGING MACHINERY TECHNOLOGY

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese