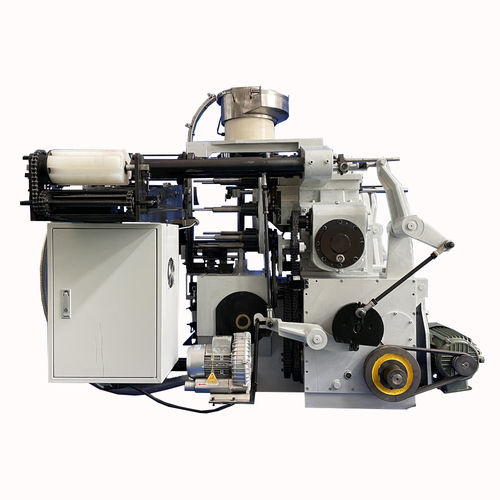

capping machine of aluminum tubes line

18000 USD ($)/Set

Product Details:

- Product Type Other

- Technology Other

- Power Source Electricity

- Operating Type Automatic

- Power 2200 Watt (w)

- Pressure 0.6~0.8 mpa

- Surface Treatment Painted

- Click to View more

X

capping machine of aluminum tubes line Price And Quantity

- 1 Set

- 18000 USD ($)/Set

capping machine of aluminum tubes line Product Specifications

- Electricity

- White

- 1600 Kilograms (kg)

- Automatic

- Other

- Painted

- 1 year

- Other

- New

- 2074*1210*1525 Millimeter (mm)

- 2200 Watt (w)

- 60 Pcs/min

- 0.6~0.8 mpa

capping machine of aluminum tubes line Trade Information

- Shanghai

- Letter of Credit at Sight (Sight L/C) Telegraphic Transfer (T/T)

- 45 Set Per Year

- 2 Months

- Yes

- Contact us for information regarding our sample policy

- Standard Export Packaging

- Asia North America Middle East

- All India

- CE

Product Description

NMD01 Capping machine is suitable for twisting caps of aluminum, lead tin, zinc and other metal tube. For example: toothpaste, shoe polish, pigment tube can be used. The feeding and unloading of the tube and cap, as well as the rotation and twisting of the cap are all automatic. The printed aluminum tube enters into the tube inlet slot of the cap twisting machine through the oven chain. The push rod pushes the aluminum tube onto the mandrel, and the detection switch detects it. If the aluminum tube is detected on the mandrel, when the mandrel stays at the upper cap position, the gripper will open, the plastic cap will fall into the gripper, and the gripper will close and hold the cap; at the same time, it will push forward towards the mandrel, and the mandrel will rotate reversely, so that the cap can be screwed onto the aluminum tube To complete the capping action. The discharge plate of the unloading station pushes out the tube with screwed cap and falls into the discharge groove.

Wuxi Yingrun Machinery Technology Co., Ltd. is located in beautiful Wuxi, China, only 150 kilometers away from Shanghai.

The company is mainly engaged in the production, sales, consulting and service of aluminum tube production line, aerosol can production line and toothpaste production line. We have more than 20 years of experience. Our products have passed the EU CE certification. Providing customers with better products and services is always our code of conduct. We also provide professional consulting and technical support to our clients.

Enter Buying Requirement Details

Other Products in 'Aluminum Tube Line' category

|

WUXI XINRUN PACKAGING MACHINERY TECHNOLOGY

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese